Spur Gear Generation!

Hello people! Bartu from project 2128 here. This summer, I was responsible with the development of a reliable software to generate spur gear pairs. First, let me tell you about the procedure we follow for gear generation.

The Procedure

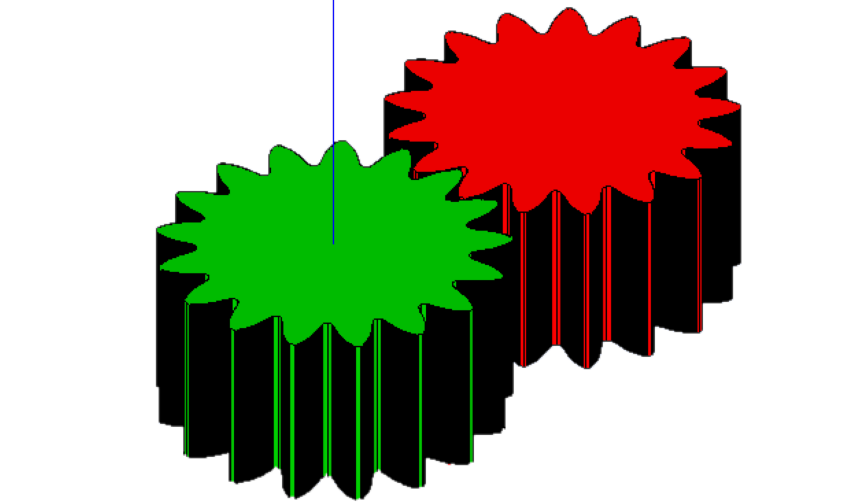

To generate a gear, we first need to calculate some points that will create the necessary curves once interpolated. For this, we use the equation of basic rack profile for spur gears to obtain the addendum part of the gear. After that, we calculate the points that are on the pitch circle and that will connect the pitch circle body of the gear to the gear teeth. These calculated points are then checked for validity and rearranged if they are good to proceed with the drawing part of the procedure. Later, straight lines are drawn between the calculated points to join them together and obtain a completed gear profile on a 2D plane. This profile is then extruded by the user specified amount, thus generating a 3D gear model. The same procedure is repeated for the second gear, which will complete the gear pair. The second gear is then translated in 2D into the correct orientation for analysis, producing the geometry shown below.

Important Considerations

We have decided to separate the process into two to allow parallelization and error handling, being more reliable for the user and easy to develop further for the developer. This way, all of the point calculations and validation checks are done in parallel outside our drawing software SALOME, essentially making it impossible for SALOME to crash. The procedure failing inside SALOME can be a real waste of time so we focused on eliminating that.

Leave a Reply